Manufacturing Services

Engineering

Alpha Magnetics focuses on Engineering Concept Design using interoperable Modeling tools. The phase of concept design is one the most important stages in product development. No other phase is as critical in determining the profit or innovation of new products. The product’s cost is very often fixed by the time they exit concept design. Engineering Concept design is a rich source of intellectual property for the company and the customer. At Alpha Magnetics we go through numerous creative concepts in order to find the best possible economic solution. We use our know-how and sophisticated software in order to estimate the potential of multiple concepts. The most attractive ones will be retained and subsequently analyzed in details.

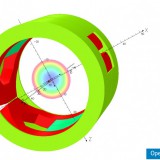

Analysis

Our company utilizes the latest Finite Element Method (FEM) software in both 2D and 3D modeling capabilities to provide our customers an accurate calculation for the magnetic field they require. Alpha Magnetics also works closely outside engineering and scientific consultants like Hurn Engineering and Management Solutions. Together we are able to find solutions to some of our more complex projects.

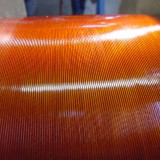

Coil Winding

Alpha Magnetics has over 5 decades of coil winding experience. With all those years of experience, we have a better understanding of different processes and solutions to some of the more difficult coil configurations that our competitors won’t even touch. There is no job too small or too big for us, prototypes, one offs or even production runs. We do them all. All our coils are tested before and after final assembly to insure the customer’s specifications are met.

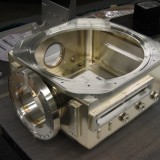

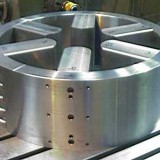

Machining

Alpha Magnetics also incorporates its own machine shop, teamed with engineering, coil winding, welding and assembly departments, we can do everything in house.

Alpha Magnetics machine shop capabilities, which includes but not limited to:

- Machining and assembly of parts

- Repair and redesign of equipment

- Welding and fabrication

- Sand blasting and painting

All of the machines are operated by our highly skilled and certified machinists with years of experience. Thorough quality control is performed on every phase of the fabrication process.

Welding

Alpha Magnetics employs advanced tungsten inert gas welding techniques (TIG) with high purity argon as the inert gas medium. Manual as well as automated orbital welding machines are at the heart of all welding operations. Alpha Magnetics adheres to stringent UHV welding standards and practices including that of non-filler material and all internal fusion weld joints. External weld joints are not used unless required for structural reinforcement and then, limited to skip or span weld configurations. In the event that a weld joint cannot be made internally, a one hundred percent full penetration external weld will be used.

Testing

Alpha Magnetics understands that well-characterized, reliable magnets are essential. Alpha Magnetics has a precision magnetic testing and metrology system, including 3-axis Hall probe, rotating coils, in order to ensure that the magnets we send to our customers will meet all specifications.

Leak Testing – Alpha Magnetics is dedicated to providing standard as well as custom ultrahigh vacuum components of the finest quality and performance. All vacuum rated components manufactured by Alpha Magnetics are leak tested repeatedly throughout the manufacturing process. All weld joints, braze joints, and seals are leak tested using a mass spectrometer leak detector.

Support

Alpha Magnetics offers full training and customer support from the time you open the crate if you need us. We offer full installation service and will come back anytime you need us for service and maintenance.